Introduction

The COVID-19 pandemic presents an unprecedented challenge to healthcare, the pharmaceutical industry’s supply chain and personnel movement. Globally different support functions like API, excipient and packaging patterners to this industry are not able to respond with in pre-defined time frame. Apart from the third-party services like calibration and annual maintenance also impacted due to travel and transportation restriction. Currently, it was big challenge for industry to serve for the society with affordable and quality medicines. Even regulators are concerned with the standard of the medicines produced and supplied across globe during this pandemic as currently it is not possible for conduct onsite inspection for international travel restriction. COVID-19 pandemic has put manufacturers, affiliates and inspectors in a new and challenging situation where it is in the public interest to continue to supply medicines while ensuring demonstrated compliance.

Background

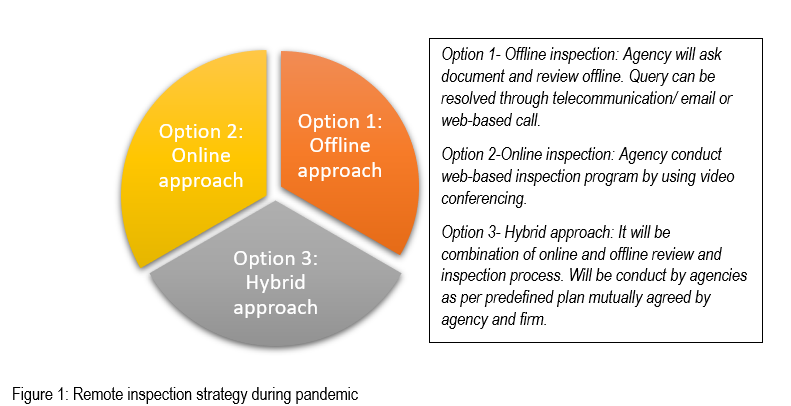

Major regulatory agencies are coming up with the strategy to audit/or inspect facility remotely to ensure continues regulatory compliance and patient safety. Here we will discuss regarding the new regulation coming up with this new strategy by few major regulatory bodies like US FDA, MHRA, TGA and European medicines agencies (EU).

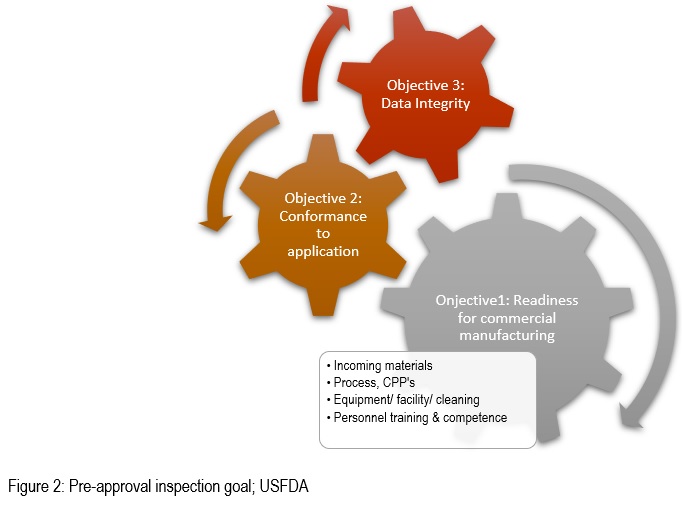

Due to the COVID-19 pandemic, FDA announced that agency is temporarily postponing all domestic and foreign routine surveillance facility inspections. These facility inspections are assigned biannually using a risk-based Site Selection Model. FDA confirmed that they will continue the quality assessment of all applications per normal assessment operations for all disciplines, where all manufacturing facilities will be evaluated using risk-based approach as per existing guidelines. During this interim period, agency will be utilizing additional tools to determine the need for an on-site inspection to support the application assessment such as reviewing a firm’s previous compliance history, using information sharing from foreign governments as part of mutual recognition and confidentiality agreements, and requesting records “in advance of or in lieu of” on-site drug inspections. 5

Nevertheless, there may be many challenges on an organization to support remote inspections. It is fundamental to assess whether the inspectee meets the technical requirements to provide remote access to electronic systems and maintain communication with and support to inspectors. The technical nuances of these systems as well as the IT policies (of the inspectee and regulatory authority(ies) performing the inspection) are likely to cause additional challenges and need to be duly taken into consideration.

However, there will be a preintimation from the regulators to make sure all the readiness can be done in well advance. Expectation to set up a common cloud platform between inspectee and inspector, where organization can upload all requested documents before start of inspection. Organization managing electronic documentation can directly provide authorization as viewer or auditor (read only) to review manufacturing, validation, testing or any development reports.

Remote inspection will take quite longer time related to routine inspection at your site. The initial success of the inspection will be built up based on the flawless communication and compatibility between inspectee and inspector. Both team members are setting together to understand well the process and practices and ensure patient safety; hence the objective of the remote inspection will be the as onsite inspection.

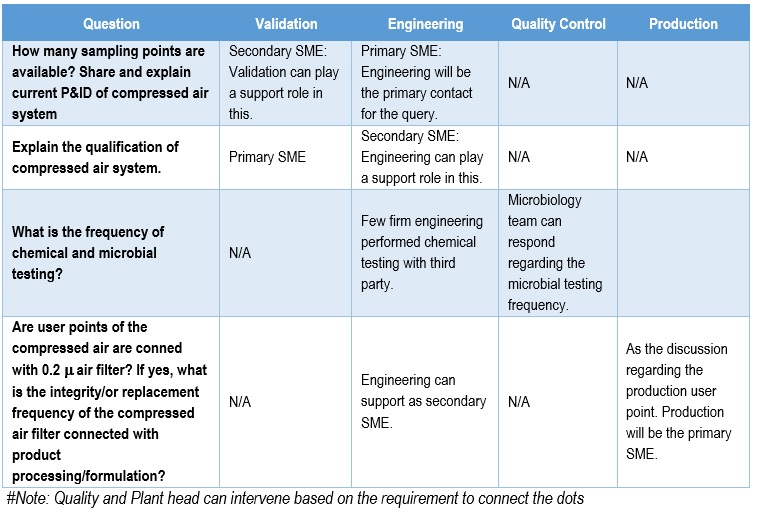

There will be a possibility where agencies will provide a detailed agenda with the name of auditor for inspection well in advance. Addition to this prior inspection agencies can ask to provide few relevant documents to understand better. Similarly, it may possible regulators can ask for consolidated list of SMEs from your organization, to whom they need to interact. So, be ready with the SME list with primary contact and mentioned if secondary or additional SME is required to support.

For example, suppose clean utility review is going on, where firm need to explain few questions regarding Compressed Air (CA) system.

Time zone between inspectee and inspector can be concern, if immediate feedback not possible to provide that need to be indicated to inspector deliberately. IT personnel will be an important part of remote inspection process to fix any kind of technical glitch.

There are several software applications (apps), video conferencing systems, interactive tools for document sharing, instant messaging apps, whiteboarding apps and meeting platforms providing the users with more real time interactive communication tools that could enhance remote working. 1

Any recording (audio / video / screenshots) during the inspection process should be notified and agreed upfront between all involved parties. 1

6TGA clearly explained few requirements of remote inspection process and urge to firm to make it available during inspection.

- The manufacturer should organize to have pre-recorded videos of the site and operations so that the inspectors can be presented with a virtual tour of GMP relevant areas.

- If the manufacturer has electronic systems for QMS databases such as complaints, deviations, OOS/OOT and other GMP relevant areas then it is requested to organize guest remote read only logins to the QMS databases for inspectors’ use at the time of inspection.

- The manufacturer must have the ability to participate in and/or host virtual communication on a suitable and agreed IT platform, with timely IT support during the remote inspection. This should include the ability to live stream video if required.

- Where time zone differences need to be taken into consideration staff including subject matter experts should be made available at the pre-agreed real-time communication timeslots.

- The manufacturer should address any other requests during the remote inspection in a timely manner to ensure a smooth process flow.

- Any information requested by inspector’s post-inspection should be provided by the manufacturer within the requested timeframes.

However, we cover all the points in this articles and expectation of all the regulatory agency at this moment is same. Regulators are quite flexible at this time to received positive response /or suggestion from firm as well.

The inspectee should provide a list of attendees for the opening meeting. This process should be followed for any subsequent meeting / session. Firm should follow their respective procedure for providing access to auditor and indicate that the validity of the authorization will be valid till the completion of inspection. Any further extension of authorization to be evaluated based on the additional request. Try to conclude every day meeting with meeting minutes (MOM), if you leave any query or concern it can be consider as ignored /or not attended. Feel free to discuss /or clarify in case you have any doubt.

MHRA aims to monitor the inspection by requesting electronic copies of documents and other information for review off-site. Any follow-up will be conducted via email and teleconferences.2

PIC/S is a confidentiality arrangement between 53 global inspectorates, mutual recognition partners and other regulators. The MHRA will rely on inspection information shared by the network to monitor international organizations and their supply chains’ compliance.2

Anyhow the reduction in inspectorate on-site presence, the Agency expects organizations to maintain GxP compliance and be prepared to take “flexible and pragmatic approaches” to ensure the protection of public health. For organizations awaiting licenses that usually require an on-site GxP inspection, it is not clear whether the agency will issue licenses without an on-site inspection or if considerable delays should now be expected. As the situation evolves, the agencies will continue to update organizations and their supply chains on its proposed approach.

7Remote audit:

Audit

performed off-site through the use of information and communication technology.

[Synonyms: eAudit, virtual audit]

Communications

FDA:

For additional questions about manufacturing changes, please email CDER-OPQ-Inquiries@fda.hhs.gov. Please include “COVID-19 inquiry” in the subject line of the email.

MHRA:

If you have any questions to MHRA on GxP-related issues, please email to below mentioned email:

- Good Laboratory Practice: gxplabs@mhra.gov.uk

- Good Clinical Practice: ctdhelpline@mhra.gov.uk

- Good Manufacturing Practice: gmpinspectorate@mhra.gov.uk

- Good Distribution Practice: GDP.Inspectorate@mhra.gov.uk

- Good Pharmacovigilance Practice: gpvpinspectors@mhra.gov.uk

TGA:

The TGA is committed to working with Australian sponsors during this time. Our staff are available to assist via the contact information below:

- For domestic and overseas inspections and general GMP enquiries, contact the Licensing and Certification Section: GMP@health.cov.au

- For overseas GMP Clearance desk-top assessments and extensions to GMP Clearances, contact the GMP Clearance section: GMPClearance@health.gov.au

- Guidance on remote GCP inspections during the COVID19 pandemic, EMA/INS/GCP/162006/2020

- MHRA announces a risk-based prioritisation of on-site Good Practice inspections during COVID-19, https://www.insideeulifesciences.com/2020/03/25/mhra-announces-a-risk-based-prioritisation-of-on-site-good-practice-inspections-during-covid-19/

- New arrangements for MHRA Good Practice (GxP) inspections due to coronavirus (COVID-19),https://www.gov.uk/government/news/new-arrangements-for-mhra-good-practice-gxp-inspections-due-to-coronavirus-covid-19–2

- MHRA Good Practice (GxP) inspections during the COVID19 outbreak, https://mhrainspectorate.blog.gov.uk/2020/03/23/mhra-good-practice-gxp-inspections-during-the-covid19-outbreak/

- Manufacturing, Supply Chain, and Drug Inspections; COVID-19, https://www.fda.gov/drugs/coronavirus-covid-19-drugs/manufacturing-supply-chain-and-drug-inspections-covid-19

- TGA expectations for overseas manufacturing sites hosting remote inspections during the COVID-19 pandemic; https://www.tga.gov.au/tga-expectations-overseas-manufacturing-sites-hosting-remote-inspections-during-covid-19-pandemic

- Extension and Expansion of Temporary extraordinary measures related to MDSAP audits during covid-19 quarantine orders and travel restrictions – Remote audits; https://www.fda.gov/media/136441/download

- Regulator Develops Remote Inspection Process Due to Pandemic, https://www.pda.org/pda-letter-portal/home/full-article/regulator-develops-remote-inspection-process-due-to-pandemic

- Drug Compliance Programs; https://www.fda.gov/drugs/guidance-compliance-regulatory-information/drug-compliance-programs

- Approaches to GMP inspection; CDER Small Business – Regulatory Education for Industry (REdI); https://www.fda.gov/media/89231/download

- GMP inspection reliance, https://picscheme.org/docview/2475

Excellent article. I certainly love this site. Stick with it!

I believe this is one of the so much important info for me. And i am satisfied reading your article. However should observation on some normal things, The website taste is ideal, the articles is really nice : D. Excellent activity, cheers